Procedure / Set Up:

Part 1: Conservation of Energy

By raising the stick to a horizontal position, we give it potential energy and when released, the potential energy is converted into rotational energy. Below we use conservation of energy and the parallel axis theorem for just the stick to find ω. We set the horizontal position of the stick, just before being released, to be at 0 GPE. ω = 5.45 rad/s

Part 2: Conservation of Angular Momentum

Since the stick is rotating about a pivot and colliding with a blob of clay it is useful to use conservation of angular momentum and the parallel axis theorem as well as our value of ω from part 1 to find ω right after to collision. it make sense for ω to be less, since the stick is inelastically colliding with a stationary blob of clay. ω = 3.14 rad/sec

The apparatus consists of a meter stick with a hole drilled at one end (pivot), and is fastened onto a small device that will allow the stick to rotate freely. Tape is wrapped, sticky side out, at the end of the stick so that when it collies with a stationary blob of clay, also wrapped sticky side out, it will create an inelastic collision. Our Job is to predict how high the clay-stick combination will rise after being released from a horizontal position by using conservation of energy and conservation of angular momentum.

We will then use Logger Pros video capture software along with a camera to find the max height and compare it to our predicted value.

Prediction (Experimental Value):

Before predicting the max height, we will need the mass of the stick, the mass of the clay, and the length of the stick from the pivot point.

M = .103 kg (Mass of Stick)

m = .025 kg (Mass of Clay)

length from the pivot is 0.99 meters.

We know that the moment of inertia pivoted at one end is 1/3 ML^2, but the pivot is not exactly at the end of the stick. Instead we will need to use the parallel axis theorem when performing our calculations.

We can predict the max height by splitting the problem into 3 separate parts.

1. The angular velocity just before impact. (Conservation of Energy)

2. The angular velocity right after impact. (Conservation of Angular Momentum)

3. The angle the stick + clay makes with the vertical. (Conservation of Energy)Part 1: Conservation of Energy

By raising the stick to a horizontal position, we give it potential energy and when released, the potential energy is converted into rotational energy. Below we use conservation of energy and the parallel axis theorem for just the stick to find ω. We set the horizontal position of the stick, just before being released, to be at 0 GPE. ω = 5.45 rad/s

Part 2: Conservation of Angular Momentum

Since the stick is rotating about a pivot and colliding with a blob of clay it is useful to use conservation of angular momentum and the parallel axis theorem as well as our value of ω from part 1 to find ω right after to collision. it make sense for ω to be less, since the stick is inelastically colliding with a stationary blob of clay. ω = 3.14 rad/sec

Part 3: Conservation of Energy

Because we are including the angle the (stick + clay) makes with the vertical we will need to write ø in terms of h, which is what we are trying to solve for. Below h' is the height we are looking for. We determined h' = 0.365m

Video Capture (Theoretical Value):

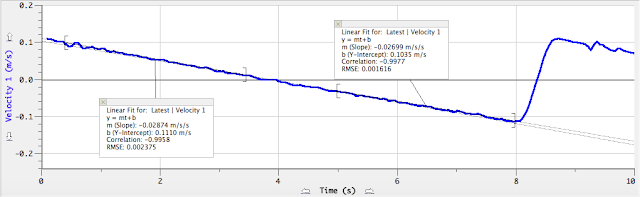

Now that we have found an experimental value for the max height, we will use Logger pro to find the theoretical value. The apparatus is exactly the same, but we are adding a camera to capture the stick as is swings and collides with the clay and rises to some height.

After capturing the motion of the stick, we analyzed the video and determined the theoretical max height to be 0.3795 m.

Comparing the theoretical and experimental values:

Experimental value: 0.3765 m

Theoretical value: 0.3795 m

By comparing our values, we were well within the range we had determined using Logger Pro. After performing a percent error calculation, we found only a 0.7905 % error.

Conclusion:

Our goal was to determine the max height a pivoted clay-stick combination will rise after inelastically colliding with a stationary blob of clay. We were able to approach the problem using conservation of energy and conservation of angular momentum. Since we did not know the moment of inertia about the pivoted point, we needed to include the parallel axis theorem in our calculations. Although our percent error was quite low, it could have included friction from the pivot or small errors when analyzing the video. Over all the experiment was a success. We were able to experimentally predict the max height and it compared well to the theoretical value.